Maintenance

The Maintenance section is located in the Actions area of each project office and is structured on two main levels:

- Plans: define the maintenance needs for material resources and PPE within the office.

- Orders: represent the scheduling of maintenance interventions.

This section also allows you to:

- Record the outcome of a maintenance task and certify its completion.

- Generate a maintenance certificate, which can be saved, edited, exported, or printed in various formats using the “Print” button.

Add a Maintenance Plan

Section titled “Add a Maintenance Plan”- Click New and select New to open the plan creation window.

- The plan may concern a single equipment item (e.g., overhead crane) or a homogeneous group (e.g., elevators). You can later link equipment registered in the Material Resources section.

- Set the validity of the maintenance, i.e., the interval between one order and the next.

- Assign the roles of Manager, Assignee, and Watcher, choosing from people, roles, or users of the office. These roles will be automatically inherited in the planned orders for that plan.

- Save the plan.

After saving, the plan will appear in the list with all indicators set to zero. If you don’t see it immediately, click Refresh in the toolbar.

By selecting the plan row, the tabs Details, Recipients, Orders, Required by, Events and Attachments will be activated below, useful for quickly reviewing or editing data.

A double click opens the plan sheet, allowing full management of the plan data and its associated orders.

Associate Equipment to be Maintained

Section titled “Associate Equipment to be Maintained”You can associate equipment intended for maintenance as follows:

- Go to the Recipients tab.

- Click New and choose among the available options:

- Equipment

- Work Environments

- PPE

- Offices

Example: by selecting Equipment, you’ll access the list of registered resources.

- Select the equipment to include and press Save. They will be listed as Recipients of the plan, with their corresponding Status:

- New: not yet managed

- Valid / Expired: based on whether a valid or expired maintenance certificate is present

Associate Resources

Section titled “Associate Resources”From the plan’s “Requested by” menu entry, you can specify which company resources require maintenance. This allows you to keep track of the link between maintenance and the specific needs arising from equipment, environments, etc.

- Select the resources to associate from:

- Equipment

- Environment

- Substance

- PPE

- Work Phase

- Task

- Homogeneous Group

- Click Next to select from registered elements

- Select the resources and click Confirm, then Finish

Schedule an Order

Section titled “Schedule an Order”Once the maintenance recipients are associated, you can schedule an order.

- From the Orders menu, click New

- Select the Maintenance Plan using “Select” All available maintenance plans for the office will be shown. If the desired plan is not listed, it needs to be created in the “Plans” section.

- Check the validity of the plan

- The roles of Manager, Assignee, and Observer are inherited, but can be edited for the specific order. If they are users, they will also be recipients of notifications for this task.

- Click Save

Register Recipients for an Order

Section titled “Register Recipients for an Order”- Select the maintenance order

- Click Recipients, then New. Only resources already linked to the maintenance plan will be available. If no recipients are associated with the plan, no resources will be shown for order enrollment.

- Select the resources to register for the order and click Save

The initial status of the order will be To be filled.

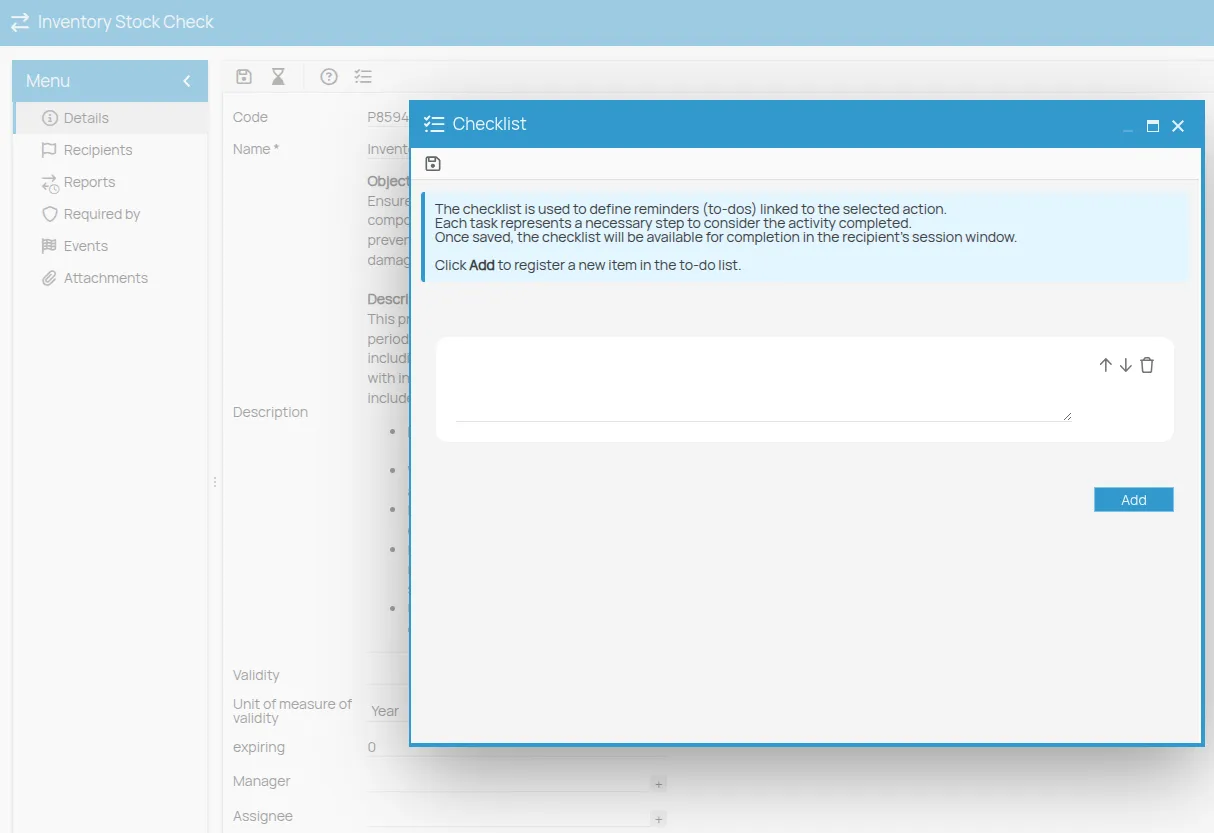

Checklist Management

Section titled “Checklist Management”The Checklist feature allows you to create and manage structured lists of activities (to-do items) associated with Procedure or Maintenance actions. Each item represents a necessary step to consider the activity complete, ensuring that all required checks are carried out before the certificate is issued.

Creating and editing checklists

Section titled “Creating and editing checklists”Checklists can be created or edited directly from the action sheet. You can access the checklist editor in two ways:

- From the action detail view, by clicking the Create Checklist button in the toolbar.

- Or by right-clicking on the action and selecting Checklist from the context menu.

When accessing a checklist from an action, the interface behaves as an editor, allowing you to define or modify the standard model of operations to be performed. Any changes made are applied to all future checklists created from that action type.

Users with the Project Administrator or Project/Site/Functional Area Manager role can:

- Create new items.

- Edit existing items.

- Reorder items to optimize the workflow.

- Delete items that are no longer needed.

Once saved, the checklist model is ready for use.

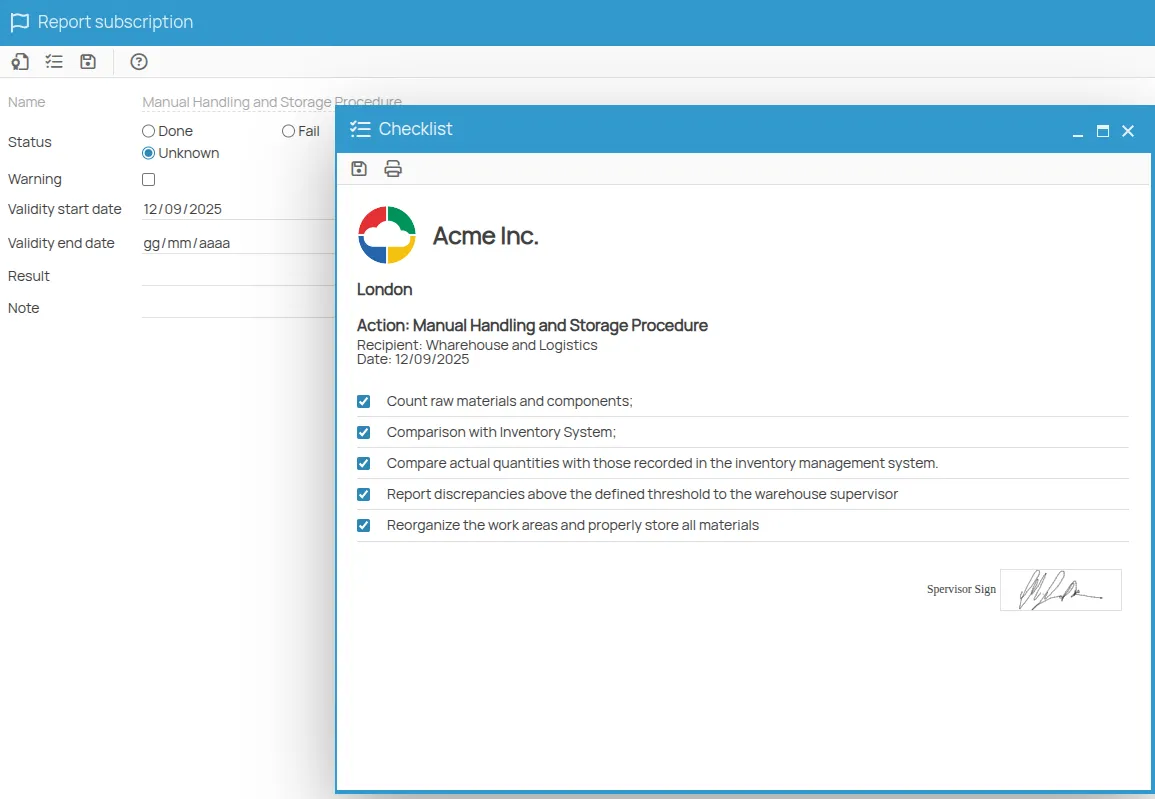

Filling in checklists

Section titled “Filling in checklists”After the model has been defined, the checklist can be filled in by the operators during the execution of an action session. Checklist completion is available only through the Create Certificate button, either from the action sheet or from the Scheduler.

During checklist completion, the user can:

- Tick off completed activities.

- Add their signature.

- Save progress and complete the checklist later.

- Generate a non-editable HTML copy for archiving purposes.

At this stage, the checklist structure cannot be modified (no adding, removing, or reordering of items).

Checklist from the Scheduler

Section titled “Checklist from the Scheduler”You can also access and fill in a checklist directly from the Scheduler. The checklist opens only if you select a row related to an action with an associated checklist and click Create Certificate.

Workflow:

- Select the row in the Scheduler corresponding to the due date of interest, related to an action with an associated checklist.

- Click Create Certificate in the toolbar.

- Specify the date when the session to be recorded in the checklist took place (the default is today’s date).

- The system checks for existing sessions on the selected date, allowing you to choose an existing one or create a new session.

- The associated checklist for the selected session opens and is ready for completion.

Register the Outcome of a Maintenance Order

Section titled “Register the Outcome of a Maintenance Order”You can record the outcome of an order in two ways: individually or using bulk mode.

Single Mode

Section titled “Single Mode”- Open the order detail by double-clicking the enrollment row.

- Fill in the form by selecting the outcome:

PassedorFailed. - Save.

Bulk Mode

Section titled “Bulk Mode”- From the edition toolbar, click Wizards, then select Bulk Edit.

- The list of resources linked to the order will open.

- Click the status badge to change it.

- (Optional) Check the “W” (warning) box to visually flag a record that needs attention: an icon will appear next to the corresponding row.

- Press Confirm to save all changes.

Generate a Certificate

Section titled “Generate a Certificate”After recording the outcome of the order as “passed”, you can issue certificates:

1. Wizard for Bulk Certificate Creation

Section titled “1. Wizard for Bulk Certificate Creation”- Click Wizards in the toolbar

- Select Bulk Certificate Creation

- A list of enrolled resources will be shown

- Select the resources for which you want to issue certificates

- Click Confirm

2. Issuance from Enrollment Details

Section titled “2. Issuance from Enrollment Details”- Open the enrollment details (double-click the row or click the icon)

- Check the start and end validity dates

- Click the badge icon, which will automatically issue a certificate for the selected resource.

Once done, the certificate is valid and visible in the expiration schedule.

Manage a Certificate

Section titled “Manage a Certificate”In the Certificate column of the “Recipients” tab, the certificate icon is now visible. It gives access to the certificate sheet, where you can:

-

Print

-

Download

-

Attach a document.

-

Click to open the certificate sheet.

-

All information related to the order and the result is shown here, along with optional notes and fields. The editable dates relate to the issue and expiration of the certificate.

-

To export the document, click the Print icon

-

Click ”…” to access the list of available templates.

-

Select the desired template from the list and click Save, then Next to access the document preview.

-

Click the “Print” icon for local printing, or click Next to export or archive it in “Files”.

Attachments

Section titled “Attachments”In “Attachments” you can link files related to the maintenance plan:

-

by adding links to existing files in “Files”

-

by uploading a new file